i-mas AD2022

Tray control by machine vision

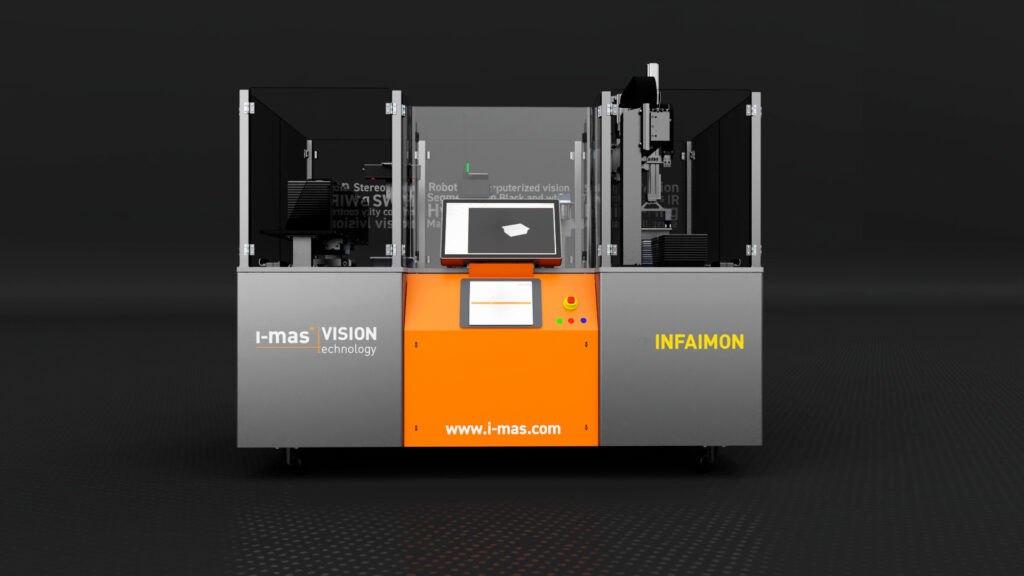

The quality control solution presented at Advanced Factories 2022, encompasses different machine vision technologies applied to Industry 4.0.

This device was designed for the purpose of carrying out inspection and detection of defects in trays using a combination of machine vision and industrial robotics technologies.

01

Challenge

Integrate automated processes with state-of-the-art embedded technology, both hardware and software, into a single machine.

AD2022 is a project that integrates engineering, automation and machine vision. The great challenge that the team has faced is to engineering has been to integrate all processes such as quality control, sorting and parts handling.

02

Development

Machine vision solutions for industry

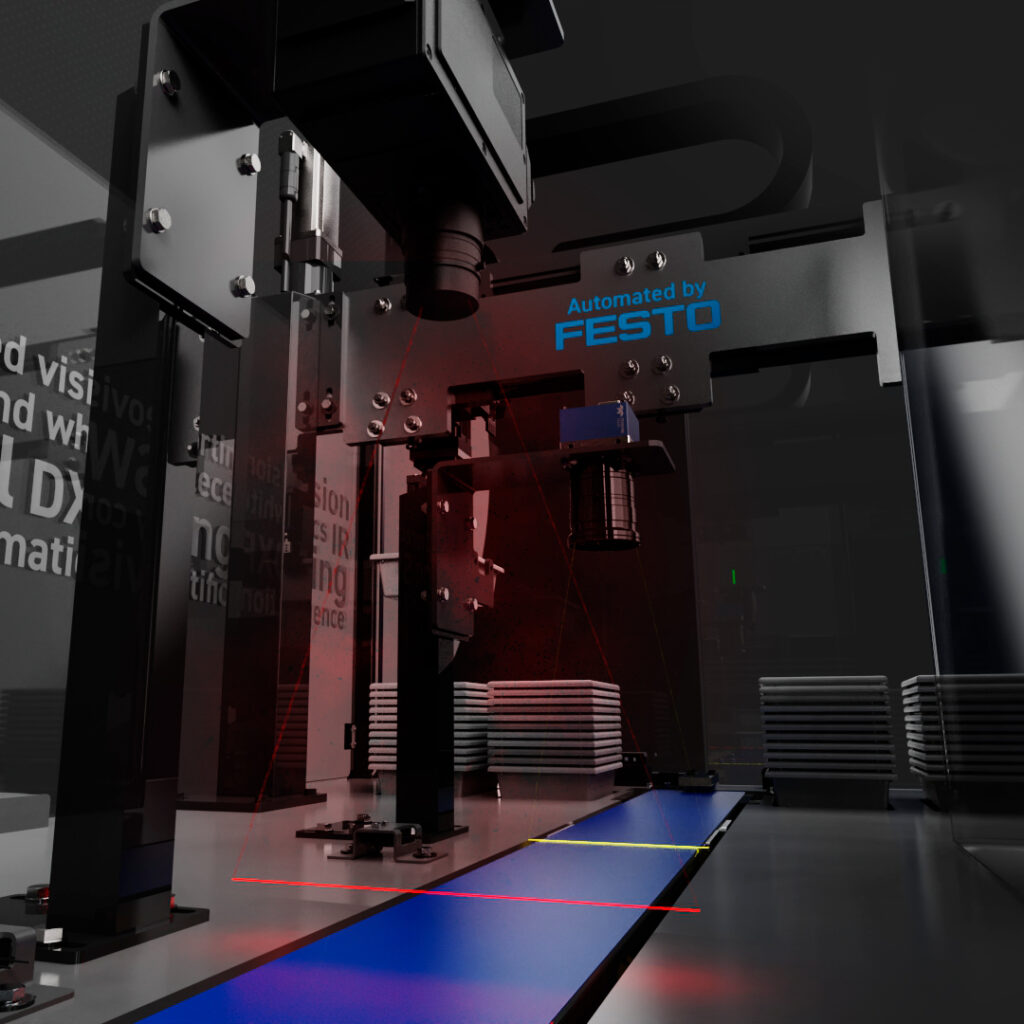

It is made up of three main components that work together. The first is a destacker, which is like a device that grabs objects and removes them from a pile or stack. Then, there is a belt, which functions as a kind of conveyor belt, moving the objects from one place to another. Finally, we have a 4-position stacker.

The stacker is a mechanism that takes objects from the belt and places them in different piles according to their destination. It consists of an X/Z manipulator, which is a kind of robotic arm controlled by a programmable logic controller (PLC). The manipulator has the ability to move in two directions, forwards and backwards (X-axis) and up and down (Z-axis), allowing it to grasp objects with precision. In addition, the stacker has two servomotors (servos) that help the manipulator to perform precise movements.

03

Final product

Tray control by machine vision

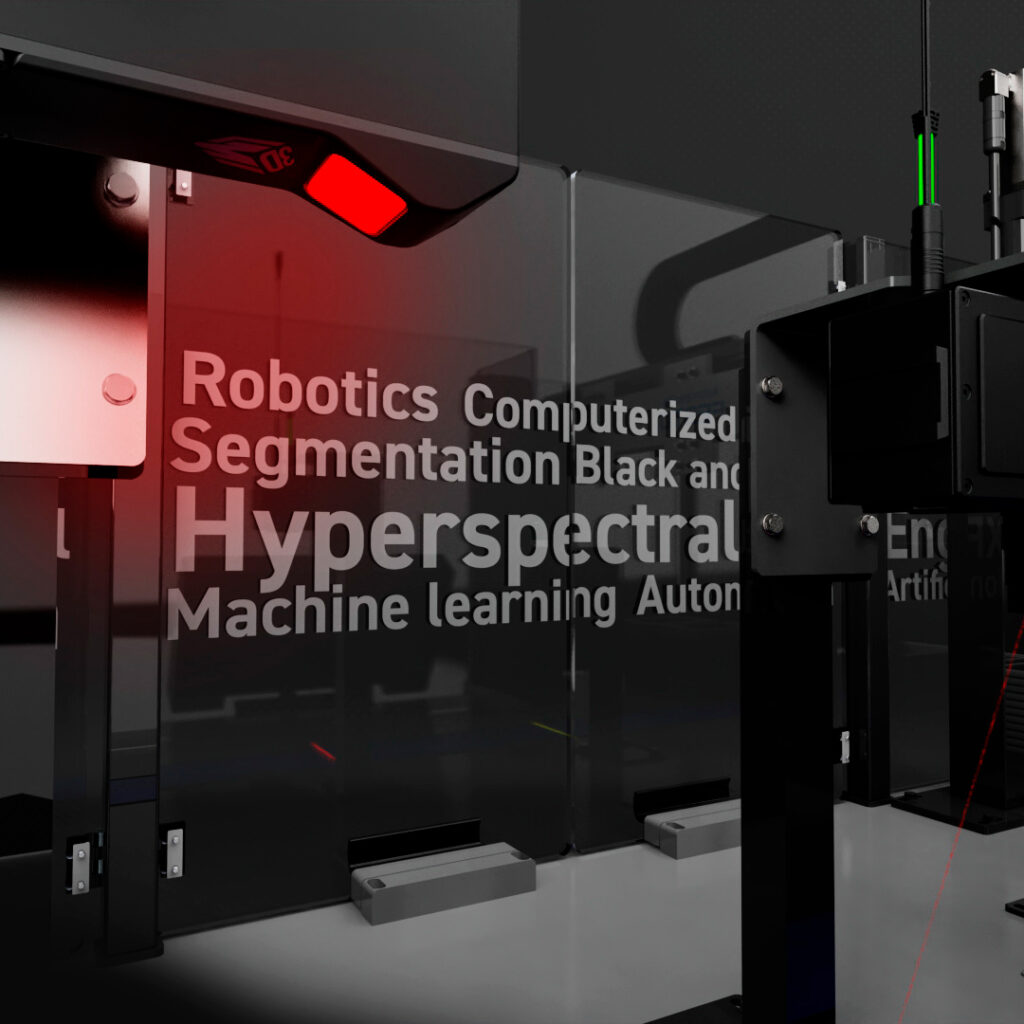

These solutions are based on image capture with different cameras and technologies such as visible, infrared, hyperspectral or structured light (3D point clouds).

Once the images are captured, traditional image processing algorithms or artificial intelligence and deep learning techniques are applied to extract results.

Typologies:

- Artificial Vision

- Deep Learning

- Innovation

- Automation

- Industry 4.0

- Design and Electronics