PROTO&GO! is the prototyping division of the I-MAS Group, a leading technological center in both Southern Europe and Latin America, with over 16 years of experience in innovation project development.

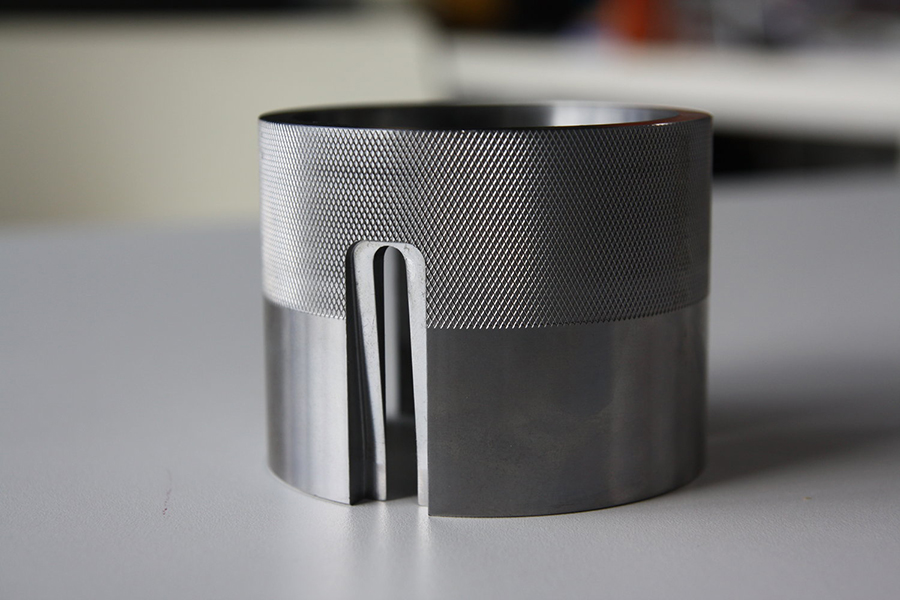

After hundreds of projects carried out in the fields of product and industrial process design and development, I-MAS has developed proprietary technologies that allow the production of 3D prototypes at extremely competitive prices through CNC machining, silicone molds, or 3D printing. The technology that makes this production platform the most efficient way to obtain prototypes is its main differentiating value, which, combined with the expert multilingual support of its sales team, makes PROTO&GO! the leading European reference in the sector.

By implementing the lean philosophy in various areas of the company, Proto&Go! succeeds in minimising the waiting times and offering quotations for prototyps in less than 24 hours through its online platform.

ABS, ABS+30% PC, EPP, EPS, HDPE, PA6, PA66, PA66+30%GF, PBT+30%GF, PC, PEEK, PEI, PEI+30%GF, PET, PMMA, POM, PP, PP+20%GF, PET, PPS+3’%GF, PPSU, PTFE o PVC.

Combining the latest technology with our team of experts allows us to obtain prototypes in a wide variety of materials and with complex geometries, achieving prototypes with the same material as the final parts.

Furthermore, thanks to the development of specific proprietary software, Proto&Go! has eliminated superfluous or low-value-added processes ranging from online quote requests to the delivery of parts within a week via express courier service to anywhere in the world.

This takes Proto&Go! a step further in industrial development and innovation, the cornerstones of the I-MAS Group , and improves both by focusing on agility in the service offering and cost optimisation in the production of single parts and prototypes.

We have RAL and PANTONE colour palette so that you can choose the colour required for each part. You can also specify whether a gloss, matt or satin finish if required.

The result is rigid or flexible polyurethane parts suitable for market testing or small series production.

Anodised, sandblasted, polished, blued, zinc-plated, chrome-plated or nickel-plated.

The PROTO&GO! platform has succeeded in digitising the manufacture of parts through an online platform, pioneering prototype manufacturing by making the latest production technologies available to any user in a simple, fast and economical way."

–Edgar Guerrero. Business Director

Competitive prices from the first part, quotation in less than 24h and parts in 8 days.

Get your prototypes now!