The industrial sector is undergoing a clear evolution towards smarter, more connected, and more efficient production models. After an initial phase focused on the automation of isolated tasks, many industrial companies are now taking the next step: adopting industrial hyperautomation as a strategic pillar of their production processes.

This approach is based on the real and coordinated integration of artificial intelligence, industrial IoT, and computer vision, not as separate technologies, but as a single system capable of making decisions in real time.

The goal is no longer just to automate, but to optimize the overall operation of automated production lines, improving efficiency, quality, and adaptability.

What is hyperautomation in industrial environments?

When we talk about hyperautomation, we are not referring to adding more robots or sensors without a clear strategy. It is about designing a productive ecosystem where data flows continuously from the physical to the digital world and is converted into specific actions within the process.

Industrial IoT enables real-time information to be captured on machine status, energy consumption, process parameters, and environmental conditions. Industrial machine vision provides critical data on positioning, inspection, and quality control. On this basis, artificial intelligence applied to industry analyzes patterns, detects deviations, and proposes automatic adjustments that improve line performance.

The result is a productive system that not only executes orders, but also learns and adapts progressively.

From isolated automation to smart production lines

For years, industrial automation has advanced through independent cells: robotic stations, inspection systems, or control equipment that function correctly separately, but with limited communication between them. This fragmentation reduces the real impact of automation on a global level.

Hyperautomation breaks this approach and transforms the production line into a coherent system. The data generated at each stage is used to adjust the rest of the process, anticipating problems before they turn into downtime, defects, or efficiency losses. Production stops reacting to errors and starts preventing them.

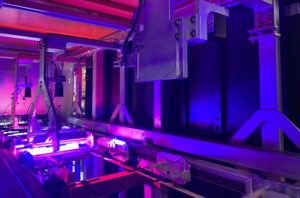

Computer vision as a driver of advanced quality control

In a hyper-automated line, machine vision for quality control is no longer an end point in the process. Inspection systems are integrated throughout the line and generate continuous information on the actual status of the product and the process.

This information not only allows defects to be detected, but also their origin to be understood. When vision data is combined with process variables and artificial intelligence models, it is possible to correct deviations in real time, adjust manufacturing parameters, and drastically reduce rejects and rework.

The role of engineering in hyperautomation projects

The application of hyperautomation has a direct and measurable impact on key industrial indicators. Unplanned downtime is reduced thanks to predictive analytics, the traceability of each part is improved, and energy and resource use is optimized.

Furthermore, by detecting and correcting errors early in the process, the costs associated with defects, rework, and waste are minimized. All of this contributes to more flexible, sustainable, and competitive production lines in an increasingly demanding industrial environment.

Ultimately, implementing industrial hyperautomation is not about adding technology, but rather about correctly designing the production process from a global perspective. Engineering capable of integrating automation, artificial vision, electronics, and software is essential, ensuring scalability, maintenance, and long-term reliability.

I-MAS and hyperautomation applied to industry

At I-MAS, we approach industrial hyperautomation projects from an applied engineering perspective, understanding each production line as a complete system that must be designed, integrated, and optimized in a coherent manner. It is not a question of implementing technology separately, but rather of connecting artificial intelligence, industrial IoT, and machine vision with each customer’s actual production objectives.

This approach allows for the development of solutions that are tailored to the reality of production, scalable, and maintainable over time, where data is converted into decisions and decisions into continuous process improvements.

Hyperautomation represents a profound change in the way we understand industrial production. Companies that commit to this approach will not only automate more processes, but will also produce better, with greater control, efficiency, and adaptability.

The future of industry lies in smart, connected production lines that are capable of learning. And that future is already underway.

Want to learn more about our services? Contact us or visit our projects section!