Machine vision has become a key tool for ensuring quality in manufacturing: it allows 100% of production to be inspected and reduces rework. But between a spectacular demo and a stable system running 24/7, there are several points where it is easy to make mistakes.

Here are some of the most common mistakes when implementing machine vision in production and how to avoid them.

1. Start with the camera instead of the problem

Many projects start by choosing the camera, lens, and resolution before defining what defect they want to detect and with what criteria. A quick test is done with a few parts, and it is assumed that it will scale the same on the actual line.

How to avoid it:

- First define the quality specification (what is OK/NOK and tolerances).

- Define the inspection “window” (field of view, defect size, speed), then select the camera, optics, and lighting.

2. Unclear or changing quality criteria

Production, quality, and customer service do not always share the same definition of an acceptable part. If the criteria are not aligned, the system may generate excessive rejection or overlook defects that later cause returns.

How to avoid it:

- Agree on physical examples of OK/NOK parts and document them with photos and measurements.

- Use these pattern pieces to train and validate the system, reviewing them when references or requirements change.

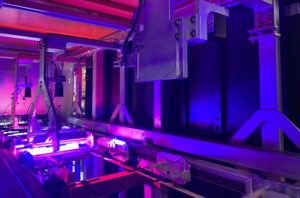

3. Underestimating the importance of lighting

The camera is usually the star of the show, but lighting is half the project. Reflections, shadows, changes in ambient light, or dirt can turn a good solution into an unstable system that gives different results depending on the shift.

How to avoid it:

- Design lighting as part of the machine: appropriate type, position, and robust mounting.

- Protect the environment from external light and establish a basic plan for cleaning and checking optics.

4. Expecting vision to fix process problems

Machine vision cannot correct poor raw materials or a malfunctioning machine: it only measures what it sees. If the process is out of control, the system ends up full of exceptions and “patches” to cover variations that are actually defects at source.

How to avoid it:

- Involve the process engineering and maintenance team from the outset and review the inspection data together.

- Use vision to locate where defects are generated, correct the root cause, and then fine-tune the algorithm and tolerances.

5. Not thinking about who will use the system on a daily basis

Designing the interface solely from the office often results in complex screens that no one wants to touch. If production and maintenance are not involved, the system is perceived as a “black box” and people avoid modifying it for fear of “breaking it.”

How to avoid it:

- Include operators and technicians in the definition of screens, messages, and usage flows.

- Show only the essentials (clear statuses, basic counters, and simple actions) and accompany this with brief, practical training.

6. Forgetting integration with the rest of the automation

Vision alone does not add value if it is not well integrated with PLCs, robots, rejection systems, or traceability. Treating it as an isolated module complicates commissioning and fault diagnosis when something goes wrong.

How to avoid it:

- Define the signal and communication scheme with PLCs, robots, and plant systems from the outset.

- Test failure scenarios before starting production (loss of image, communication, or synchronization) and document the expected response.

Computer vision with results: the I-MAS approach

A good machine vision project is not measured solely by the accuracy of the algorithm, but by its ability to work every day in production, with real people and live processes. When these common mistakes are avoided, machine vision becomes a lever for improving quality, productivity, and traceability, rather than a perpetual pilot project.

At I-MAS, we support companies throughout the entire project cycle: feasibility analysis, pilot testing, integration with automation, and plant commissioning. If you are considering implementing or improving a machine vision system, we can help you do so in a realistic and results-oriented manner.

Want to learn more about our services? Contact us or visit our projects section!