When developing a new product, controlling each stage of the process is the difference between a promising idea and a product that actually reaches the market. In an environment where deadlines are getting shorter and global competition is increasing, companies need more than just a supplier: they need a partner capable of accompanying them from design to final delivery.

At I-MAS, we view 360° manufacturing and assembly as a comprehensive philosophy. It is not just about producing parts, but about managing design, prototyping, machining, assembly, and final verification in a unified manner, ensuring quality, consistency, and traceability at every step.

Product design and development: from idea to finished product

It all starts with an idea. From there, the design and product development team translates customer needs into viable solutions, taking into account materials, processes, and functional requirements. This approach allows us to anticipate potential manufacturing or assembly issues from the conceptual stage.

The next step is prototyping, an essential stage for validating the design before moving on to production. Thanks to the combination of 3D printing and CNC machining, a real version of the product is obtained, allowing tolerances to be adjusted, assemblies to be verified, and costs to be optimized.

Once the design has been validated, the product moves on to the industrial machining workshop, where the final parts are manufactured using materials and finishes equivalent to those used in mass production. Precision at this stage is key to ensuring smooth assembly without rework.

Assembly: where design comes to life

Final assembly is much more than just a stage of assembly. It is the moment when engineering, logistics, and quality come together. At I-MAS, we manage the entire process internally, from component procurement to functional and aesthetic verification of each unit.

Having our own assembly area allows us to:

- Reduce errors resulting from outsourcing.

- Control the final quality of each manufactured product.

- Ensure consistency between design, manufacturing, and assembly.

- Optimize delivery times through unified management.

Each project is delivered complete, verified, and ready for use or integration, eliminating external dependencies and ensuring full traceability of the process.

Integration of industrial processes for greater efficiency

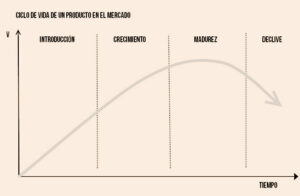

360° manufacturing provides a unique advantage: vertical process integration. Designing, manufacturing, and assembling under one roof means reducing communication times, avoiding errors due to information transfer, and having a complete overview of the product life cycle.

This integration also improves adaptability: when faced with a design change, a functional modification, or a new product version, the design, workshop, and assembly teams work together to implement improvements immediately.

In a market that demands flexibility and speed, having total control over the production process is a tangible competitive advantage.

Quality, traceability, and final delivery

Quality control accompanies the entire workflow, from dimensional verification of machined parts to functional inspection of the assembled unit. Every component, every step, and every validation is recorded, creating a traceable history that guarantees reliability and transparency.

Finally, the product is delivered fully assembled, tested, and ready to be shipped to the customer or to the market.

A process that combines engineering, manufacturing, and assembly in a single space, transforming an initial idea into a tangible reality.

I-MAS: The future of integrated manufacturing

The trend toward full integration of industrial services not only improves results, but also redefines the relationship between engineering and the customer.

At I-MAS, we believe that the future of manufacturing lies in offering comprehensive solutions, where technology and experience combine to bring any idea to its final version.

Because when design, manufacturing, and assembly are aligned, the result is not just a product. It is a solution ready for the market.

Want to learn more about our services? Contact us or visit our projects section!