Moving from prototype to series production is one of the most critical points in product development. During this transition, industrial electronics often change more than meets the eye: a prototype may work in the laboratory but still not be ready for stable, repeatable, and scalable production.

The leap to series production is not just about manufacturing more units. It involves adapting the design and processes so that the customized electronics can be reliably integrated into a real production environment, with rhythms, demands, and constraints that are very different from those in the laboratory.

Electronic prototyping: from the laboratory to industrial reality

In the prototype phase, electronics mainly act as a validation tool. The system architecture is checked, different technical solutions are tested, and parameters are quickly adjusted. Electronic prototyping allows for rapid learning, reduces uncertainty, and confirms that the product is viable from a functional point of view.

This environment is, by definition, flexible. Iterations are frequent, component changes are acceptable, and testing is usually manual and exploratory. The focus is on answering one key question: does the solution work?

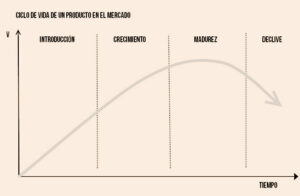

When the product goes into series production, electronics change roles. They cease to be a means for experimentation and become a structural part of the product. They must behave in the same way unit after unit, during thousands of cycles of use and under real operating conditions. The priority is no longer simply “it works” but “it always works and is manufactured consistently.”

Electronic design and PCB design intended for manufacturing

In production, PCB design is analyzed not only for its electrical performance, but also for its direct impact on electronics manufacturing. Aspects such as ease of assembly, inspection, test access, and process stability take on decisive importance.

The board must adapt to the expected production rate and minimize variability between units. A well-thought-out design facilitates repeatability, reduces line incidents, and contributes to smoother manufacturing. The goal is no longer just for the electronics to work, but for them to be manufactured continuously and predictably, without relying on manual adjustments or constant intervention.

Electronic testing and quality control in production

When testing becomes part of the production process, it ceases to be a one-off activity and is integrated into the production process. Electronic quality control ensures that each unit meets the same standards before leaving the factory and provides traceability throughout the production cycle.

In addition to detecting possible deviations, testing generates valuable information about the process itself. The data obtained allows trends to be identified, stability to be improved, and a consistent level of quality to be maintained over time. Unlike manual prototype testing, verifications in production must be repeatable, objective, and compatible with the pace of the line.

Scalability, embedded firmware, and industrial connectivity

Mass production introduces a new requirement: the ability to evolve the product. Embedded firmware and connectivity become key tools for maintaining, updating, and diagnosing electronics in real-world conditions.

In solutions with industrial IoT and different connectivity systems (WiFi, Bluetooth, LoRa, NB-IoT), electronics must operate stably in demanding environments and facilitate remote diagnostics. Thinking about scalability means assuming that the product is not static, but will evolve in volume, functionality, and support needs over time.

I-MAS: End-to-end electronic development and electronic manufacturing

The transition to series production requires an integrated vision: electronics, mechanics, software, and processes must fit together as a system. This approach reduces uncertainty, accelerates industrialization, and improves maintainability.

At I-MAS, we approach this as an end-to-end electronic development, from design to electronic production in Barcelona, providing electronic solutions for industry that are aligned with each customer’s reality.

From prototype to series production, the objective changes: from validation to stable production. When design, process, testing, and support are considered as a whole, industrial electronics ceases to be a risk and becomes a reliable basis for scaling the product.

If your company is looking for electronic solutions for industry or a partner capable of transforming an idea into a manufacturable and scalable product, contact us and discover how to turn your project into a solid industrial solution.