In today’s industrial environments, where operational efficiency and machine availability are critical, maintenance is no longer a purely reactive task.

Thanks to advances in industrial automation, computer vision, and artificial intelligence algorithms, it is now possible to implement automated preventive maintenance strategies that anticipate failures before they occur.

From corrective maintenance to preventive automation

Tradicionalmente, el mantenimiento se dividía en dos grandes enfoques: correctivo (actuar tras el fallo) y preventivo (intervenir de forma periódica para evitar averías). Sin embargo, ambos enfoques implican una serie de ineficiencias: paradas imprevistas, intervenciones innecesarias o desgaste prematuro de componentes.

Industrial automation applied to maintenance allows for the implementation of a predictive approach based on constant analysis of the actual condition of equipment. Thanks to sensors and artificial vision systems, it is possible to monitor variables such as wear, lubrication, vibration, or the presence of physical defects in key components in real time.

How does a predictive maintenance system with computer vision work?

The key lies in the use of high-resolution cameras installed at strategic points along the production line. These cameras capture images or videos of the machines in operation, which are then analyzed using artificial intelligence algorithms. The system identifies visual patterns that may indicate:

- Color changes or loss of shine on lubricated surfaces.

- Cracks, scratches, or deformations in critical parts.

- Debris, dirt, or leaks in mechanical components.

- Displacement, slack, or loosening of components.

All this information is collected and compared with historical records of optimal machinery performance. If deviations exceeding a defined threshold are detected, the system can generate automatic alerts or even trigger real-time responses, such as controlled equipment shutdown or the issuance of a maintenance order.

Key benefits of machine vision systems compared to traditional inspections

Incorporating machine vision into preventive maintenance offers significant advantages:

- Continuous monitoring without human intervention, which improves safety and reduces errors.

- Early detection of potential faults, preventing unexpected downtime.

- Optimization of maintenance resources, intervening only when necessary.

- Integration with SCADA or MES systems, enabling process automation and complete traceability.

- Improvement of product design and development by identifying weaknesses during prototype testing or initial production.

Applications in different industrial sectors

In sectors such as automotive, it is common to use cameras to check the condition of welds, check belt tension, or detect micro-defects in metal components. In the food sector, the wear and tear of blades, conveyors, or cutting systems is monitored. And in the pharmaceutical industry, machine vision is used to ensure the correct closure of vials, the condition of caps, or the accuracy of dosing systems.

These use cases demonstrate that the combination of automation, machine vision, and AI not only reduces operating costs but also improves the quality of the final product and the traceability of each batch manufactured.

What should be taken into account when implementing these systems?

The integration of this type of solution requires:

- A good definition of the critical points to be inspected.

- Cameras and sensors suitable for the environment (humidity, temperature, vibrations, etc.).

- Algorithms trained with real data from the production environment.

- A technological infrastructure capable of processing and acting on data in real time.

In this regard, it is essential that product design companies work from the early stages of prototyping to anticipate how these artificial vision systems will be integrated into future production lines.

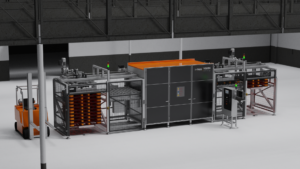

I-MAS: artificial vision at the service of smart maintenance

At I-MAS, we work on developing industrial automation solutions tailored to our customers’ real needs. From the product design and prototyping phase to the integration of sensors, cameras, and intelligent analysis systems, our multidisciplinary team combines engineering, software, and AI to optimize each stage of the product life cycle.

If you are looking to improve the reliability of your machinery, reduce unplanned downtime, and anticipate failures with advanced technology, we can help you.

Want to learn more about our services? Contact us or visit our projects section!